Additive manufacturing offers many benefits over traditional manufacturing methods, including faster turnaround times, reduced costs, and greater flexibility. In this blog post, we will discuss the advantages of additive manufacturing for printing 3d turbo pumps and how it can help your business!

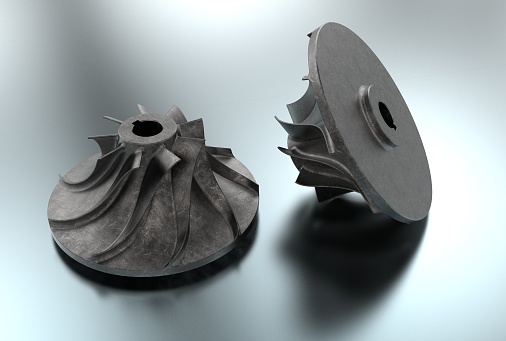

3D printing is a manufacturing process that creates objects by depositing material in layers. It has been used to create everything from eyeglasses to prosthetic limbs, and it is now being used more and more to print turbo pumps. Turbo pumps are used in a variety of applications, from oil and gas production to power generation. 3D-printed turbo pumps offer a number of advantages over traditional pump manufacturing methods. They can be produced quickly and easily, with little waste. 3D-printed turbo pumps can also be customized to meet the specific needs of each application. As a result, 3D-printed turbo pumps are becoming increasingly popular in a wide range of industries.

Additive manufacturing is being used more and more to print 3d turbo pumps. These pumps are critical components in many industries, including automotive, aerospace, and energy. additive manufacturing offers many benefits over traditional manufacturing methods, including faster turnaround times, reduced costs, and greater flexibility.

Additive manufacturing, also known as additive manufacturing 3d printing, is a process of making three-dimensional solid objects from a digital file. It is done by additively adding material layer by layer to create an object. 3D printing is being used more and more to print turbo pumps. Turbo pumps are widely used in many industries such as automotive, chemical, oil and gas, aerospace, and so on. They are used to pump fluids at high pressures and speeds.

The benefits of additive manufacturing turbo pumps include but are not limited to design freedom, lightweight, Increased efficiency, and cost savings. With additive manufacturing, there is no need for tooling or machining, which can save time and money. Also, additive manufacturing allows for complex shapes that would be impossible to produce with traditional manufacturing methods. 3D printed turbo pumps are being used more and more in many industries because of their benefits.

The benefits of additive manufacturing don’t stop there! 3d printing also offers design flexibility that traditional manufacturing methods cannot match. With 3d printing, you can easily create complex geometries and internal features that would be difficult or impossible to produce using other methods. This gives you the freedom to design the perfect pump for your application.

Aluminum 3d printing is a key technology for printed 3d turbo pumps. Aluminum is a strong and lightweight material that is ideal for high-pressure applications. additive manufacturing allows for the pump to be printed in one piece, which reduces assembly time and costs. In addition, aluminum 3d printing offers superior surface finish and dimensional accuracy compared to traditional manufacturing methods.

If you are looking for a 3d printed turbo pump, aluminum 3d printing is the way to go. With its many benefits, it is the perfect solution for your high-pressure application needs!