Professionals bring experience, skill, and knowledge to the table. They know how to install a custom pool correctly and efficiently. They also have access to tools and materials that aren’t easily available to the public.

Constructing a pool isn’t a task that should be done by the average person. Working with a professional is the best option to ensure safety and the highest quality of work.

Safety

A professional pool builders based in Melbourne has the right skills and tools needed to install or construct a quality swimming pool. This ensures that your pool will not only look great but also be safe for your family to use. In addition, they can easily purchase building materials and equipment at a cheaper price than you would be able to.

Furthermore, they have access to various design options and construction materials, including concrete and fiberglass. They can also recommend the best option based on your budget, requirements, and preferences.

Additionally, they will take into account various factors during the installation process, such as proper excavation techniques, soil conditions, and proximity to existing structures. This will minimize the risk of leaks or other problems that may affect your pool’s lifespan. Furthermore, they will adhere to electrical safety standards and prioritize the placement of grounding and insulation to prevent hazards like shocks or fires. They will also handle any required permits or inspections, saving you the hassle of handling these tasks yourself.

Peace of Mind

Professional pool builders have a wealth of experience and are aware of the various aspects involved in the construction of a swimming pool. For expert pool maintenance services to keep your pool in top condition, visit Striking Pools at ( https://www.strikingpools.com.au/services/pool-maintenance/ ). They are skilled in coordinating excavation, plumbing and electrical work, landscaping, and even permits and inspections. They will also ensure that the job is completed on time and on budget. They are also insured and will be able to cover any potential damage that may occur during the construction process.

A pool builder will also be familiar with the different types of materials that are available for the construction of a pool. They will be able to offer advice and guidance on what the best option is for your needs, space and budget. They will know which products are high-quality and aesthetically pleasing. This will save you the hassle of shopping around for different building materials, which can be quite costly.

When choosing a professional pool builder, be sure to research and interview several candidates. Check for reviews and testimonials, as well as their licensing, insurance and Better Business Bureau rating. Be wary of builders who provide extremely low estimates as they may be cutting corners somewhere.

Cost-Effectiveness

Building a pool involves many different tasks, from excavation to plumbing and electrical work. Attempting to do this yourself is dangerous and expensive, particularly because there are unforeseen challenges that may arise during the construction process. A professional will have the right equipment and knowledge to anticipate these challenges and overcome them quickly and efficiently.

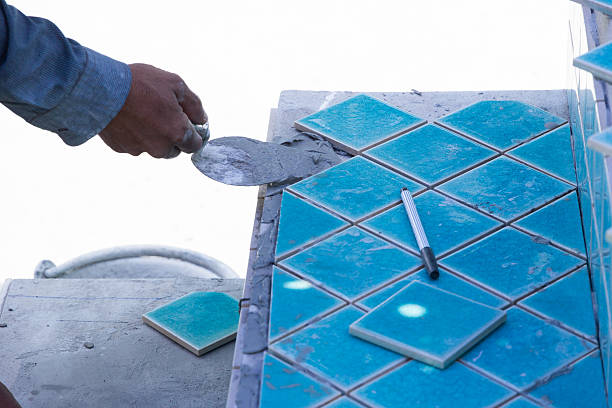

In addition, a professional will save you money by buying the materials that you need at discounted prices. They will also help you choose high-quality, stylish materials for your swimming pool. These materials add value to your property and can enhance the look of your home. From mosaic tiles to decorative woodwork, the professionals will find aesthetically pleasing and durable materials for your pool.

Licensed contractors understand the permits and laws that must be followed when building a pool. This makes the entire procedure much easier and ensures that your pool is built safely. Furthermore, they will take care of the inspections and permit requirements for you, which alleviates a huge burden from you. In addition, they will provide after-sales support if there are any issues that require attention.

Time-Saving

Having a pool can add a lot of value to your property. But maintaining it can take time and energy. Hiring a professional can make things more manageable for you. This is because they know the whole procedure and can help you build your dream pool.

Besides, they can also save you the hassle of visiting shops looking for building materials. They have connections with reputable suppliers who offer premium materials that are designed for durability and style.

They can even help you navigate the process of getting the necessary permits. This can be a hassle, especially for homeowners who are not familiar with the legal requirements. A professional pool builder knows all about the laws and regulations and will help you avoid costly fines or other legal complications down the line.

Customization

Professional contractors have a wealth of experience and knowledge that you just can’t get from DIY. They understand engineering, functionality and aesthetics which allows them to construct a pool that is both stunning and effective. They also have a wide variety of building materials and can source unique pieces that would be difficult for you to find or afford.

One of the most important benefits of working with a professional is that they will work with you to create a detailed design plan for your pool, which means that you can be sure your new pool will meet your exact specifications. They will help you to make changes until you are happy with the design, so that when it comes time to start construction, you won’t have any surprises in store.

Additionally, some professional pool builders offer additional services such as 3D design, ecological water treatment, and home automation management teams, which can be very useful in the long run. Make sure to inquire about these additional services when you’re selecting a contractor, so that you can ensure that your project will be completed within your desired timeframe.